The safety of your workplace and the wellbeing of your employees can be key elements when you’re running an industrial business. Getting the safety right can positively impact your operations, it can increase your workforce’s productivity also resulting in better results.

Safety related problems, no matter how small they’re going to cost you money, time, resources, and they also have the potential to damage the reputation of your business.

In this article, we’re going to talk about seven workspace safety tips for all industrial businesses out there.

1) Consistently Train Your Workforce

This can be the most essential point in the entire list. Proper training reduces the workspace’s risk. The Occupational Safety and Health Administration (OSHA) did a study on injury prevention programs and found it reduced the circumstances by up to 60%.

The best way to cure a safety related incident is to prevent it from happening in the first place. Employees would have a lot of things going on in their heads. The safety training they did at joining can’t be recalled. Therefore a periodic safety training would refresh their skills and would give them practical learning.

2) Perform Regular Inspection.

Create a habit of doing routine checks with supervisors and make sure to review the hazard and safety suggestions across all departments. The supervisor needs to be responsible for running down the daily checklist for his department.

You can also review the past injuries, and illnesses of your workforce and can come up with a corrective safety action. Make it a regular habit for the supervisors and you’ll start to identify the root cause of hazards.

3) Take Housekeeping seriously

Your housekeeping isn’t only for a clean and shining workspace, but it’s crucial for the safety of your employees as well.

According to a report from the Bureau of Labor Statistics, tripping and falling at the workplace is the second most reported cause of occupational injuries. If there is a spill, make sure to clean it immediately. Regular thorough housekeeping will also prevent the workspace from nails, glass, or any other sharp materials projecting from the floor.

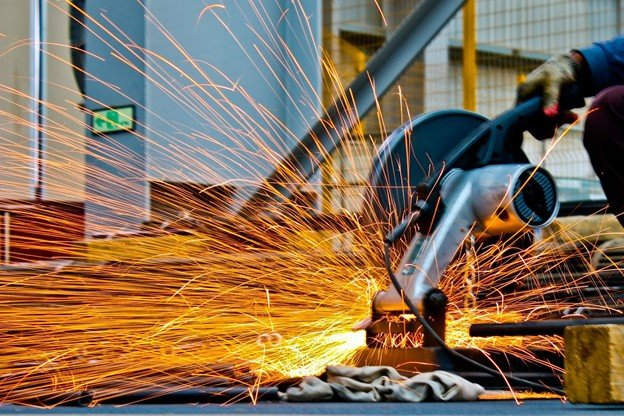

4) Allow Authorized Employees to use Machinery

If someone isn’t officially trained to use certain equipment, don’t let them use it. If you’re dealing with big machinery in your facility, and if someone makes a small mistake with it, some changes might end up in operational malfunctioning.

Avoid your mature employees (who are trained to use the equipment) to delegate small operating tasks to newbies. It may sound tiny, but the impact can be critical.

5) Time to be creative

If there is a workspace safety incentive program for your employees, it can do the heavy lifting for you. When there is a reward to keep the best practices in place, there will be motivation. It can be one of the effective ways to make your employees consciously maintain their workspace.

That’s it. Implementing these five tips can benefit your business and your workforce.